EE 2212

EXPERIMENT 4

16 February 2017

Report Due: Thursday, 23 February

Diode ID-VD

Measurements and the Half Wave Rectifier

PURPOSE

Ø Use laboratory measurements to extract key

diode model parameters including IS, n (also called η or N in

SPICE) from the ID-VD measurements of the 1N4001. All specifications except the (Peak Reverse

Voltage or the Peak Inverse Voltage) PRV (PIV) should be virtually identical

between the 1N4001 (PRV=50 volts) and 1N4002 (PRV=100 volts). PRV or PIV is the Peak Reverse Voltage; Peak

Inverse Voltage as provided by the manufacturer. Thou shall not exceed the PRV(which

would be tough to do in the EE 2212 lab)!

Ø Implement designs of the half wave

rectifier circuit and measure time domain characteristics and the transfer

characteristic.

Ø Measure and compute ripple voltage as a

percentage and as an rms value. You can use both the soft-keys on the

oscilloscope or the multimeter.

Ø Compare individual diode results and

circuit results using SPICE simulations.

COMPONENTS

Ø 1N4001 Diodes (Use the 1N4002 diode model

in SPICE)

Ø 100 and 1 kΩ

resistors

Ø 0.1 μF,

1μF, and 10μF capacitors Actual values not critical since you

are just showing the “filtering/smoothing” effect to minimize ripple voltage.

PROCEDURE

ID-VD

Characteristics and Diode Model Parameter Extraction

Ø

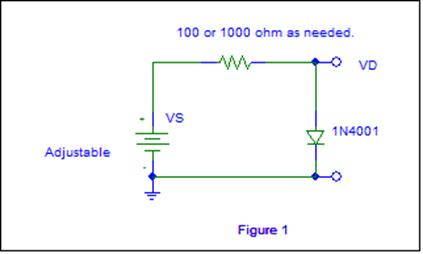

Using SPICE, simulate the circuit shown in Figure 1.

Obtain the ID-VD characteristic curve for the

1N4002 in SPICE over

a range at least of 0 to 0.8 volts for VD and find the diode current value for the diode when VD = 0.7 volts. For this, it might be useful to use a DC

voltage sweep in conjunction with a VDC source. In addition, you will need to

change the x-axis value to be the voltage across the diode (v+) – (v-) under Plot_Axis Settings…_Axis Variable…-

Ø

Examine the model characteristics for the

1N4002 PSPICE, which can be

found

by selecting the device and then Edit_Model…_Edit

Instance Model (Text)… You will use this information

forcomparing to your measurements.

Ø

Construct

the Figure 1 circuit. Use the multimeter to measure ID and the multimeter also to measure VD. Note the ID is measured by measuring the voltage

across the resistor and dividing by R, that is apply Ohm’s Law. Pay attention to the diode orientation. The

banded side is the cathode end. Change the

supply voltage VS to adjust ID to the desired current

setting, then measure VD. Take enough readings to accurately define

the diode characteristic. You should

measure out to ID

values of a few mA. Record

your results in a data table in both your laboratory notebook and in your

laboratory report. EXCEL calculations

and the graphing function really works well.

Ø

I discourage the use of the multimeter for measuring current directly because very

often the internal fuse in the mutimeter is “blown”,

that is open-circuited, given the high usage factor in EE 2006

and it is a stinker to replace! I will

explain what not to do!!! Use Ohms law to obtain current by measuring the

voltage across the series resistor. The

power supply ammeter is not as accurate for this current measurement.

Ø

Consider the equation  which approximates to

which approximates to when the diode is

forward biased. To facilitate graphing

over a number of orders of magnitude we obtain and graph,

when the diode is

forward biased. To facilitate graphing

over a number of orders of magnitude we obtain and graph,

Note that log(base

10) e = 0.434

Note that log(base

10) e = 0.434

Ø

From

this equation, determine and fit a straight line (linear regression) to your

plotted ID-VD semi-log graph. Your equation will be in

the form y = mx

+ b. I suggest referring to Problem Set

4.

Use

these data to find Is and n. Compare to the SPICE model parameters. Virtually all calculators have the linear

regression (least squares linear fit) built-in.

Be sure you know the procedure.

It will make your life easier.

Alternatively, you can create an EXCEL spread sheet and use the spread

sheet algorithm for the curve fit. The

graphing function in EXCEL also works well!

Half-Wave Rectifier

Ø

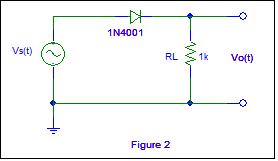

Refer

to Figure 2. Change to the signal

source to a 10

volt peak-to-peak 100 Hz sinusoid. Perform a SPICE transient analysis simulation

and observe the half-wave

rectified output. Also note the effect of

the diode offset voltage when you compare the input and output waveforms. Observe and plot Vout(t) and the transfer

characteristic, Vo vs Vinput.

Ø

Experimentally

observe the operation on the oscilloscope in both the time domain and as a

transfer function.

Ø

Now

we want to “smooth out” the pulsating DC by using capacitors. Place a

C across the 1 kΩ resistor. Now use all three values of C to illustrate

the change in the

ripple voltage by measuring

Vout(t). Use the ”Measure”

menu on the oscilloscope to measure the

rms voltage of the output using dc and ac

coupling. Explain the differences in these measurements

and explain what these measurements are illustrating. Use your diode model and check your lab

measurements using SPICE. Observe that

ripple voltage is defined as either the (DV/Vpeak) x 100%

or as

Ø

(Vrms or as Vrms of the output-voltage/Vpeak)x

100% )x 100%. Watch your polarity on the

electrolytic capacitors or else ![MM900336554[1]](Experiment4DiodesAndRectifiers_files/image010.gif) Also, since electrolytic capacitors have a broad tolerance, their values

must be checked on the capacitance meter

to obtain accurate results.

Also, since electrolytic capacitors have a broad tolerance, their values

must be checked on the capacitance meter

to obtain accurate results.

(An added historical note: The background screen is a photo of a “cat

whisker” diode used as an AM radio detector in the 1905-1920 era of early radio

before the widespread use of vacuum tubes.

A sharp springy wire (cat whisker) formed a pressure (point contact)

junction with a galena crystal. Galena

is PbS (lead sulfide) and

has a bandgap of about 0.4 eV. Of

course, the underlying physics was unknown at the time. Primitive, but it did work-sort of. A reincarnation of this was used by soldiers

in World War II in what is called a “foxhole radio”. The junction for detection of strong AM radio

signals was a sharp wire contacting a “blue edge” razor blade to form a

crude junction. The metallurgical “bluing” process to harden

the steel cutting edge on the single edge razor blade of the time creates a

difference in the work functions between

the wire and the metal razor which results in a rectifying junction.

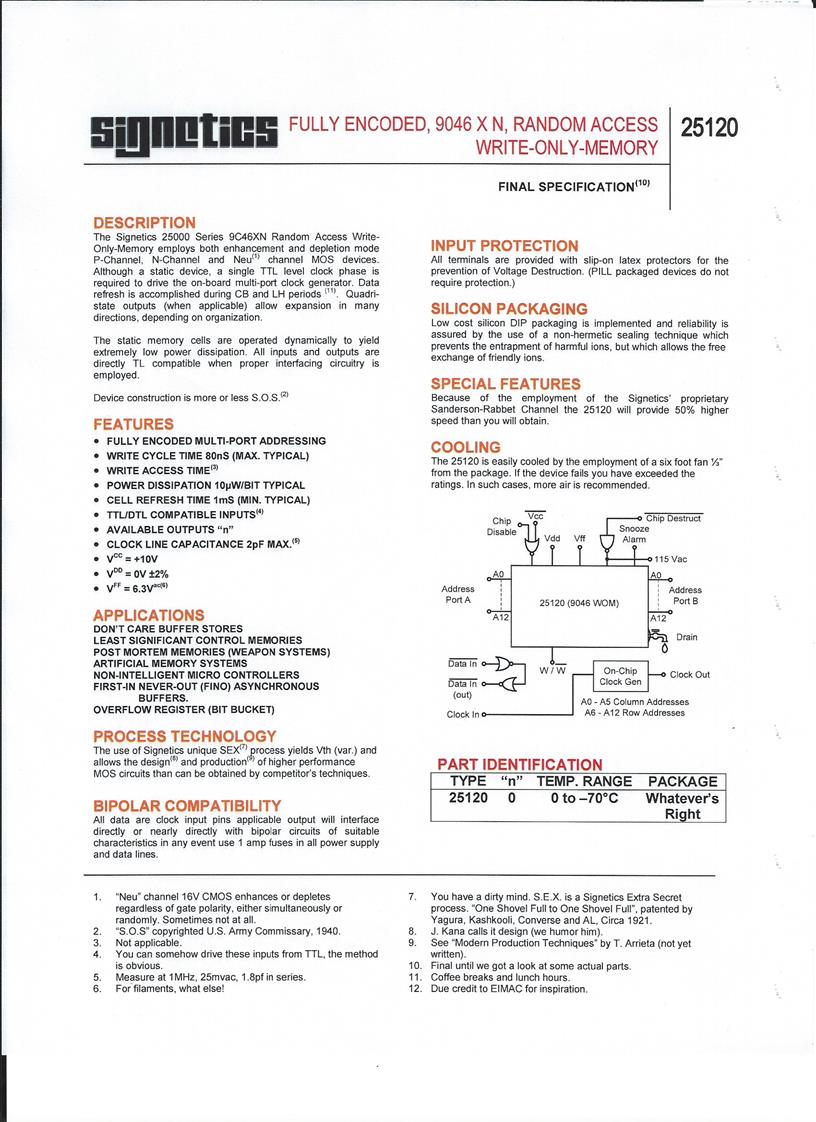

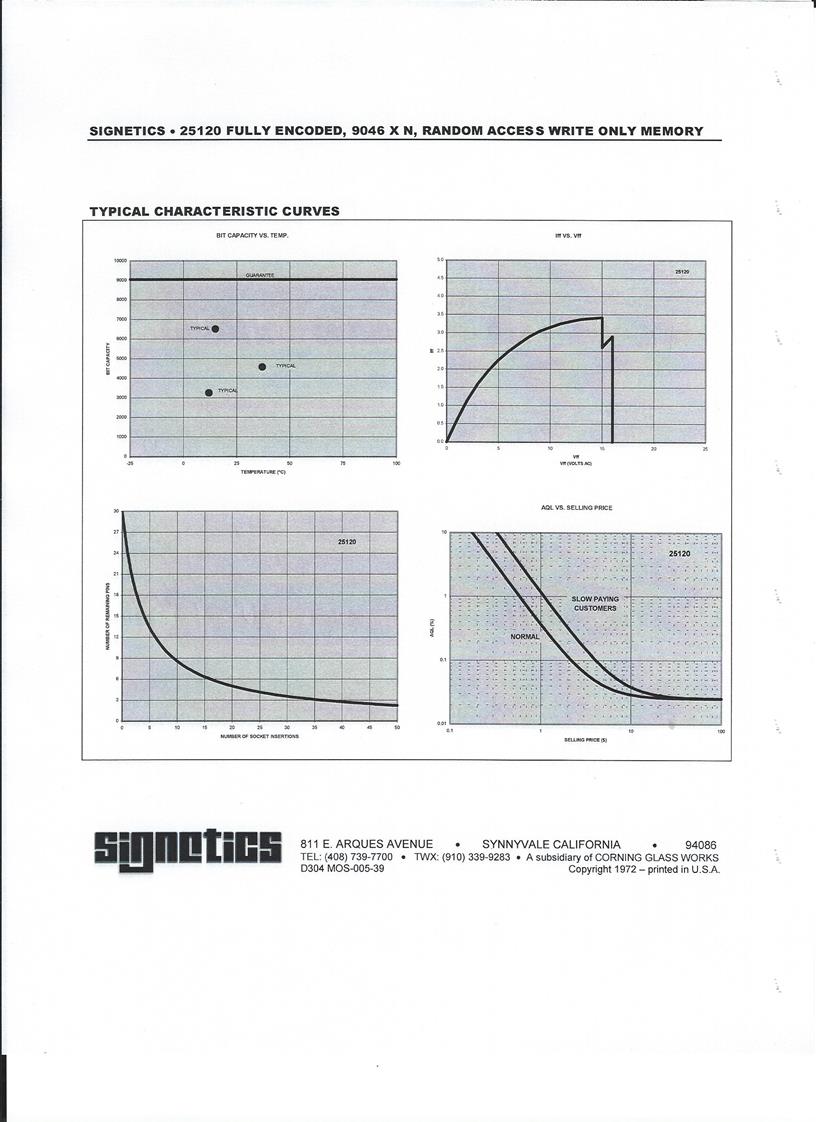

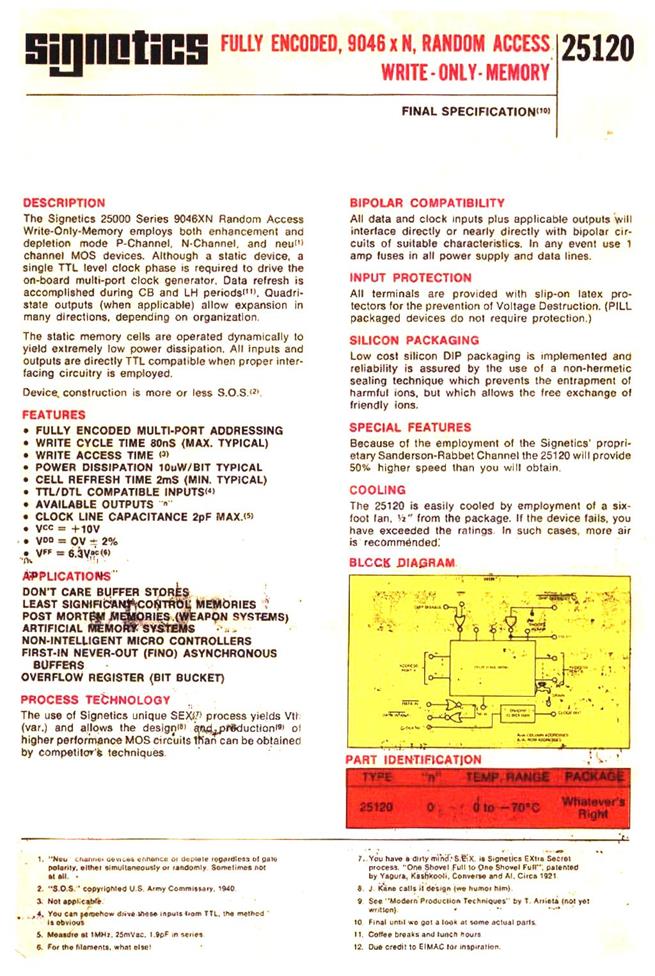

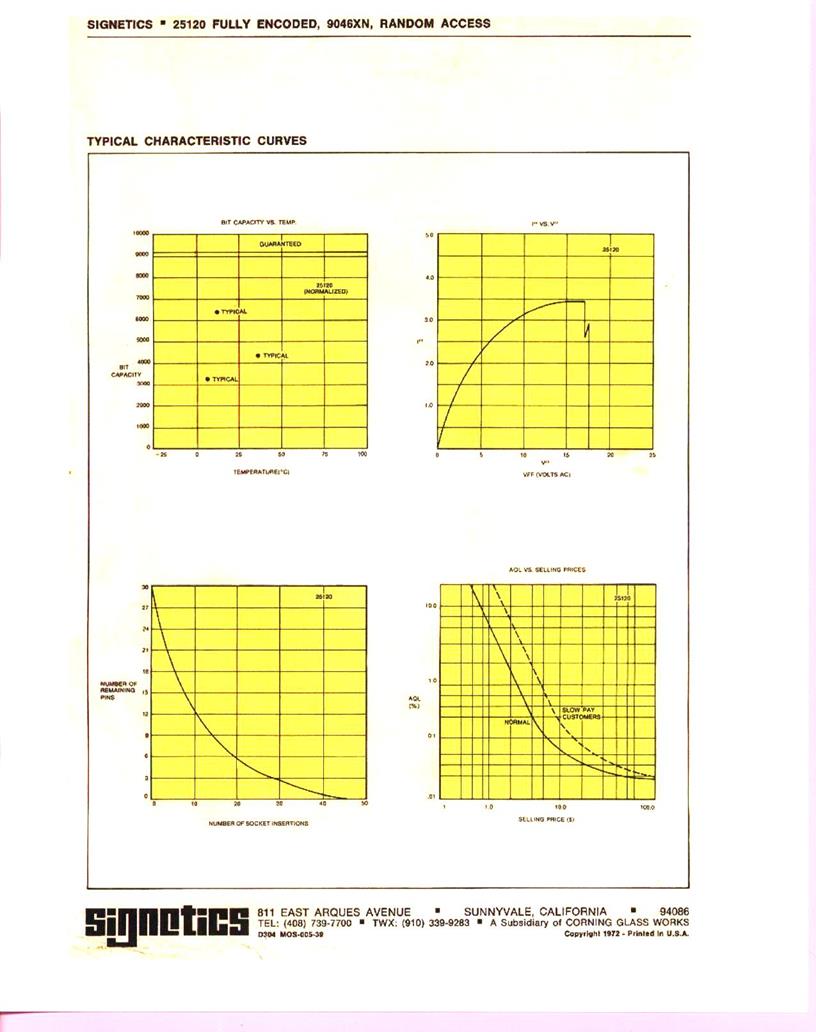

This is the historically classic data sheet for a Write

Only Memory produced by Signetics Engineers with too much time on their hands and probably written over

a long liquid lunch. This data sheet actually

slipped by the Signetics Quality Control managers and was published in a data book

before the “joke” was discovered. It has

become a classic in the semiconductor industry. I was never able to find out if

there was a subsequent employment issue with the engineers involved but things

were different in the industrial world in those days. Read it carefully including the footnotes

for this “Write Only Memory”

and enjoy!